Product & Technology

FOCUS TECHNOLOGY

Platform-based Control System

Necessity of Platform

Necessity of Platform

Platform is an environment that the system is running. It provides environment that can be edited according to business characteristics and users can use it in any form depending on any purpose.

When different applications are loaded on one platform due to differences in hardware and in products of inspecting function, it causes to a lot of maintenance loss.

When new functions are added, current application should be updated through the process of compile, moreover, it costs much of time consuming and loss of human labor by such as risk of history management, re-verification of reliability at each facility.

In addition, closed development environment of application that even user cannot edit ‘its Work Flow’ brings the result of bounding to the development company. The most common types of quality problems in the tester are mainly developer’s mistakes modified in the field rather than defects of equipment components.

Backgrounds of Platform Development

Backgrounds of Platform Development

Based on the know-how of performance and reliability testers of automotive electronic control devices starting from 2001, we are favorably commented upon customers by applying embedded script engine and user-editable scheduling based technology to testing systems. By this platform, we acquired GS (Good Software) certification in 2008.

Since then, through continuous technology development, we have developed a protocol for high-speed data communication. The completed platform that have the function of bi-directional emergency processing function and is able to be applied in various environment have been distributed in 2017.

-

2016: Implementation of REPS MCA site

- - MCA GEN3-REPS TESLA EOL production line

- - Applying DEVICE-NET User edit support

- - UI Improvements

-

2014: Implementation of Production EOL Line (CEPS)

- - MDK 33rd ~ 36th CEPS EOL

- - Modification Support in various EPS models

- - Application of automatic pattern conversion

-

2012: Implementation of Production EOL Line (REPS)

- - MDK 31st REPS EOL production line

- - PLC Interface & Motion Technology

-

2010: Patent Application

- - Applying patented technology protocol for high-speed communication

- - Applying Bi-directional emergency message processing

-

2008: GS Certification

- - Application Development with user-based editing technology based on PEP-6000

- - GS(Good Software) Certification

- - Implementation on testing equipment

-

2001-2007

- - Continental Script & Pattern operating technology developments & applying test equipment for Continental Automotive’s Tester

Control System based on Platform

Control System based on Platform

Based on the development know-how of performance and reliability tester of automotive electronic control units(ECU) since 2001, we have developed hardware distributed control system (model : PEP-6000 Series) for low cost and high efficiency from 2007, it is now available PEP-8000 Series with steady upgrade.

Control system with Embedded Operation System has self-synchronize timer based on hardware and is able to configure Real-time Measurement System using Data acquisition board(DAQ) and Motion control board.

Production EOL Line Testing system is designed to operate based on control system PEP-8000 series.

Platform of Performance and Reliability Tester

Platform of Performance and Reliability Tester

Based on embedded script engine and user-editable pattern scheduler, user can directly create and execute function list and DV Plan on the given environment. Performance and Reliability Tester is a testing equipments that determines whether ECU is abnormal in the case of executing environment test on ECU more than 1,000 hours.

Therefore, it can proceed load application and evaluation simultaneously using multi-threading. It also has error-tracking functions and every kind of analysis functions. Moreover, user can easily interlock with chamber by protocol which can control chambers.

Platform of Production EOL Line Tester

Platform of Production EOL Line Tester

This platform is able to proceed bi-directional emergency messaging applied protocol for high speed data communication. It provides the development environment that determine the product’s conformity with embedded script engine and user editing function.

For Production EOL Line Testing systems, control system (PEP-8000 series) performs a vital role in testing because it tests the finished products. It includes motion-control functions using various PLCs and servo motors.

Furthermore, it is possible to allow flexible response by interlocking and monitoring functions to protect test equipment. It also provides functions counting production on a day, counting defective products and analyzing measured value of each item.

SETUP

SETUP

Customer, development company and tester manufacturing company can cooperate closely and is able to distribute each role. By this, production line and testing equipment setup can be completed in a short time with reliability

-

Customer Company

Product Test Layer

Customer Company

Product Test Layer

Development of Product Test System

- - Function Test Set-up

- - TDevelopment of Test System

- - Education & Training of engineers

-

LINE T/O Company

Tester Equipment SET-UP Layer

LINE T/O Company

Tester Equipment SET-UP Layer

Setting-up Test Equipment

- - Implementation based on Platform (Measurement Instruments & Hardware, etc.)

-

FOCUS

System Development Layer

FOCUS

System Development Layer

Development of System Integration

- - Support of Technology

- - API Development Support Specialized in Test Equipment

- - Education and Training for Setting-Up

Expectation

Expectation

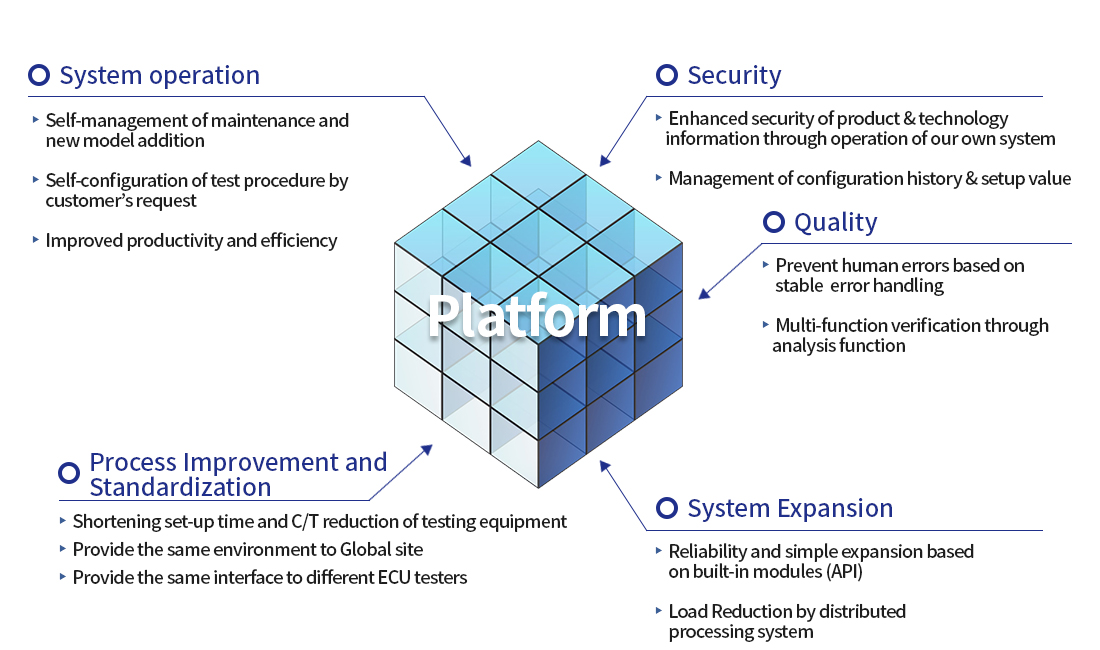

The expected effects of applying the platform are as follows.

Application example

Application example

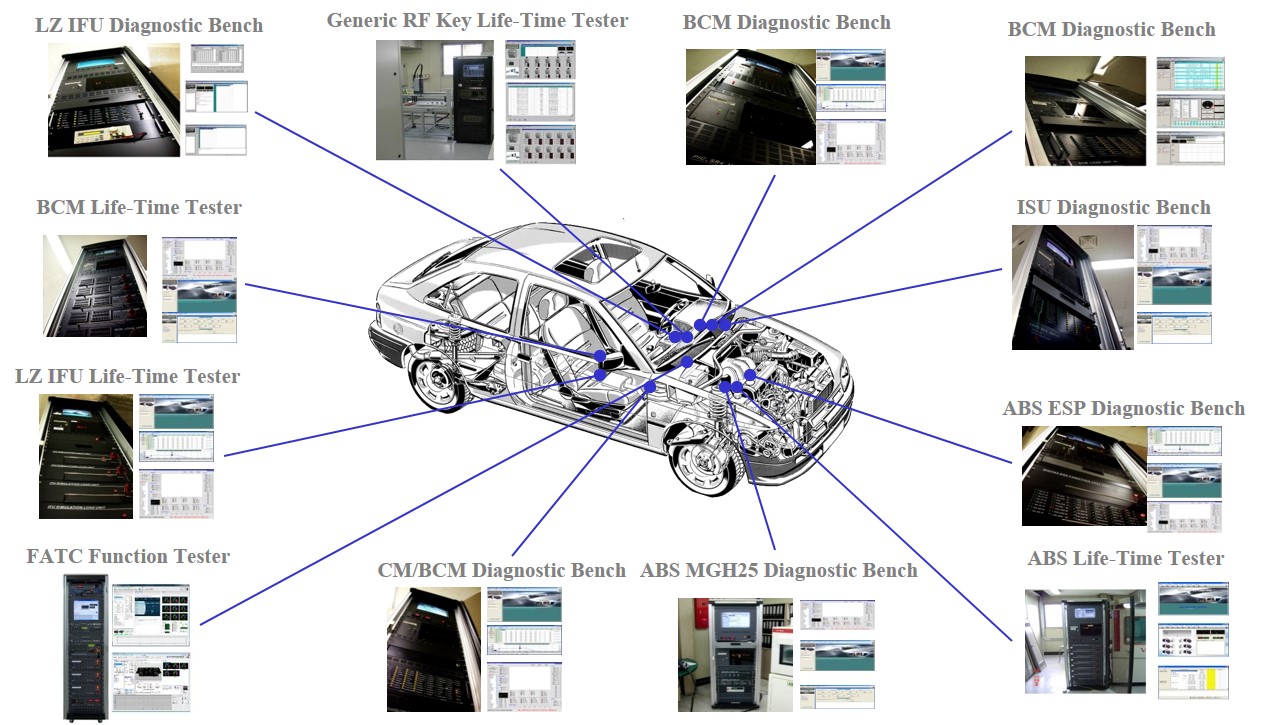

Our performance and reliability testers have been constantly supplied and used by Continental Automotive and Mando which are automotive parts developer and suppliers since 2002, and have been expanded global corporation in USA, India, Iran and China.

EOL (End of Line) Tester equipment have been continuously supplied in CEPS / REPS production line at Mando since 2012, which are planning to expand it to Global site.

CUSTOMER CENTER

We will listen carefully to our customers.

Corporate inquiry

Corporate inquiry